描く Blog #3 #ZoneOneWinter

Aim: 13 mins/500words

12/26/25: Friday

10:27AM-10:38AM: #11mins

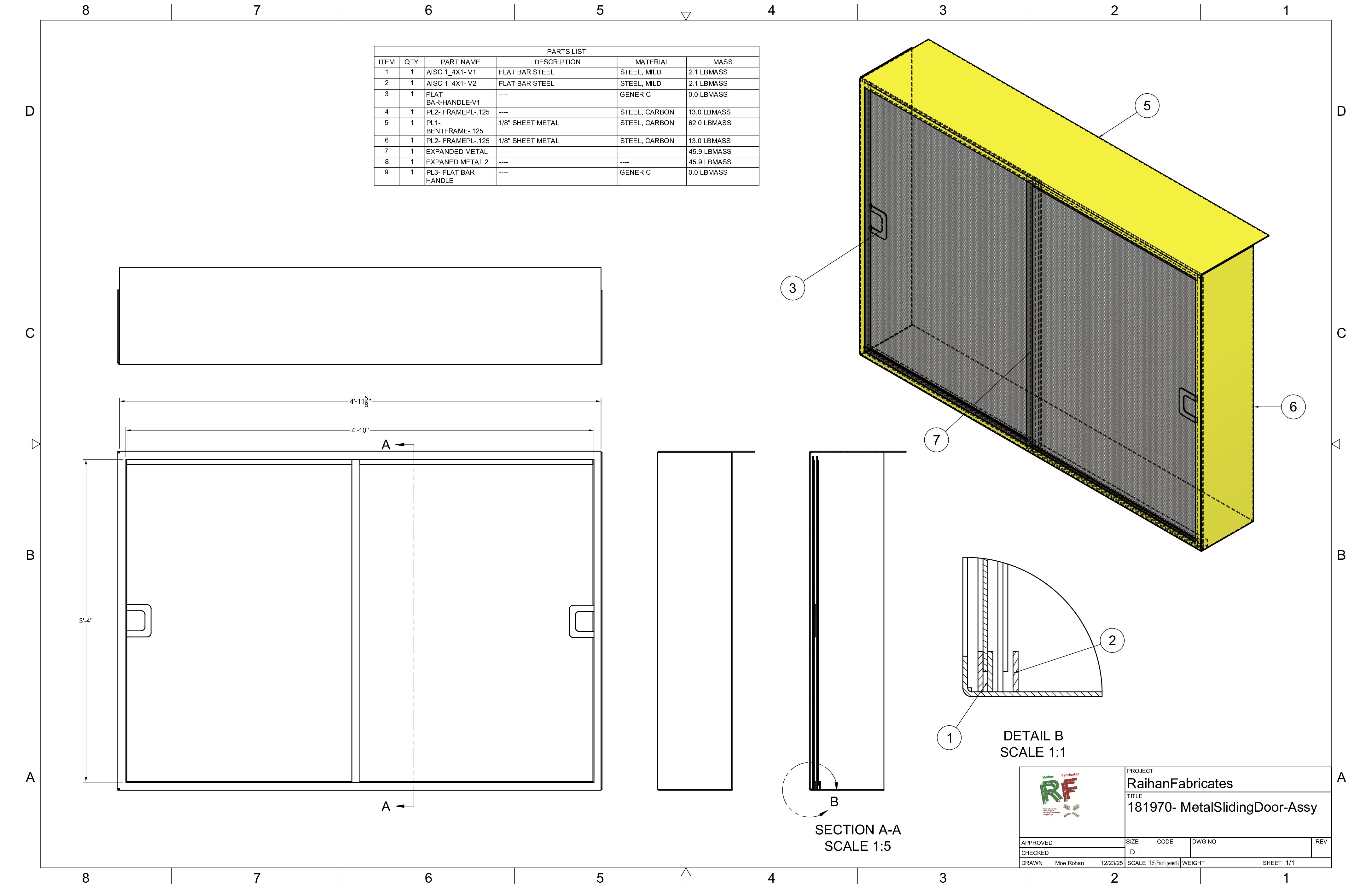

[[Fabrication Drawing]]

[[Expanded Metal Drawing]]

[[Bent Plate Drawing]]

[[Flat Bar Drawing]]

To RaihanFabricates Audience,

Today I will be sharing a drawing that I have of Sliding Steel Door that I did at Logan Steel last year. It’s a simple drawing, but it was fabricated, and I thought I would showcase it on this site. I have a pretty decent rendering of the sliding door, and I think it’s pretty cool how it came out. And while I was doing this, I figured out, with the help of my site specialist, Rahim, how to actually make 3d files on my website as well. The app itself is not mine, but it exists in wordpress, and it’s pretty neat.

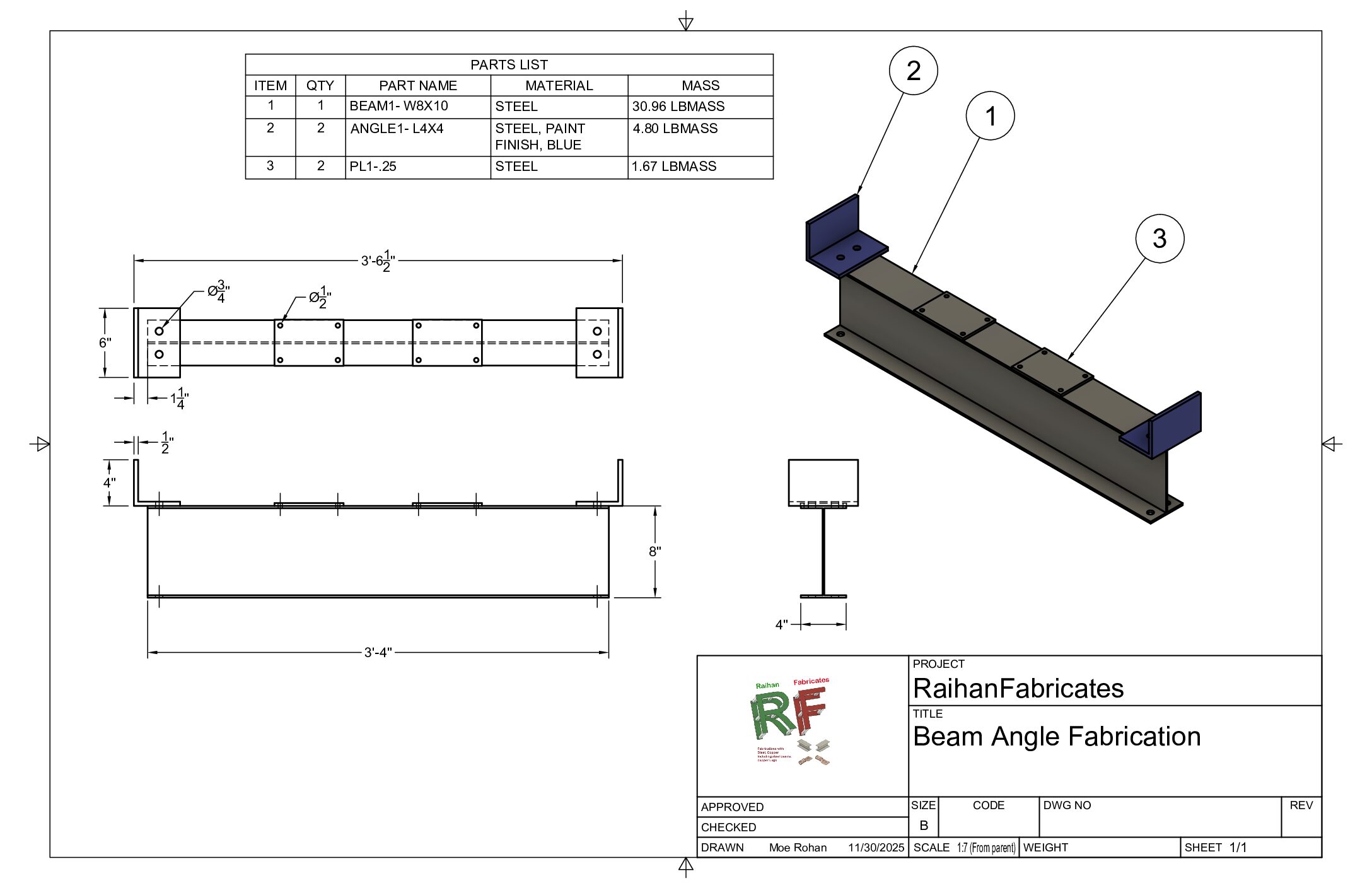

I can now put 3d models onto my site, and this is super exciting for me. It’s pretty simple, and though you will need blender, to get the proper file. And once you export that file, and then you can upload it onto the site. I learned this yesterday, and now I will be able to properly showcase this fabrication piece. The drawing and the video that is attached with this, it’s a demonstration of the design process. I’ve been experimenting with Autodesk Fusion, as I have a year of license now. So it’s a pretty impressive software, and I don’t think it’s any less than Solidworks or Inventor. I think if I use it long enough, it will be even be better.

One cool thing about Autodesk Fusion, it has the S shortcuts that I learned while using Solidworks. I come from a background of using Autodesk Inventor, as I have been using it since August of 2022. And I genuinely love using Autodesk Inventor, because you can play with shapes in so many ways, and because it’s a mechanical engineering software, the way you play with constraints, it’s a lot more intuitive, I think. And because of that, I genuinely have a lot more fun making models. It’s not easy, but once you get the hang of working in 3D, it’s really fun. And I genuinely enjoy it a lot.

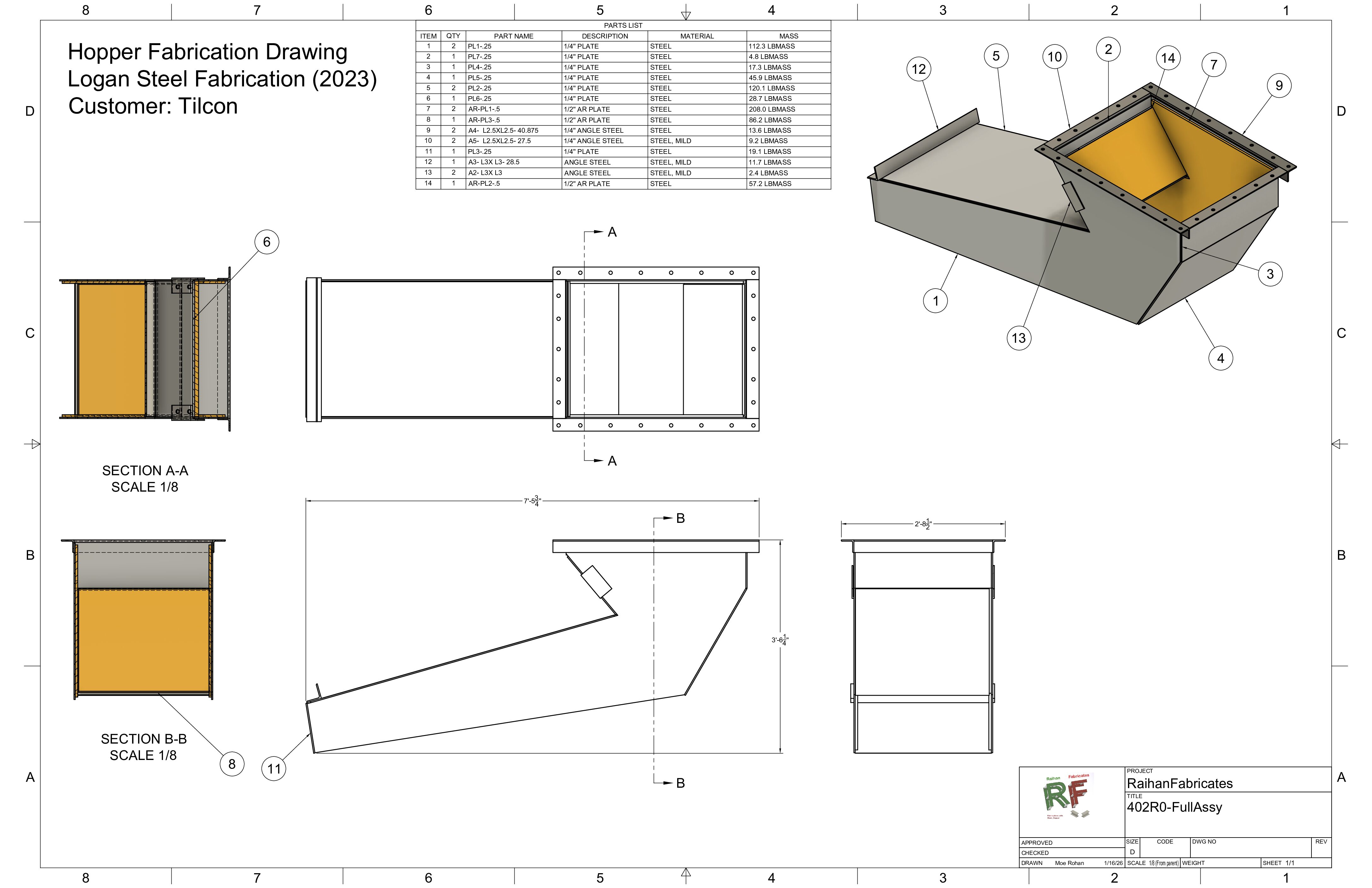

For this blog, I’m just going to do a simple demo. The Sliding Metal Door is basically made out of two big plates. One will need a bunch of bends, which is the main piece, and then another small piece (these are the yellow main frame pieces), and then they are welded. The other pieces are the door handles, the door itself, that were made out of expanded metal, and it’s really neat, because you do get standard sizes, and then you just have to SAW cut it to proper size. I also have flat patterns for all the pieces, but I’m not showcasing here, as I just want to put a demo of some of my past works.

This fabrication also includes some flat bar steel, which are just bars, in this case, it’s 1/8” thick steel, 3” wide, and around 5’ length. It’s pretty much a simple sliding door, with some mechanisms so it works out in the field. The hardest part is conforming the steel to the shape, and then properly welding based on the drawing, and the location it demonstrates. This is another simpler fabrication piece, that looks simple, but obviously it’s steel, it’s not that easy to make. And that’s the extent that I have for today.