描く Blog #2 #ZoneOneFall

Aim: 12 minutes

12/11/25: Thursday

9:48AM-10AM: #12mins

#600words

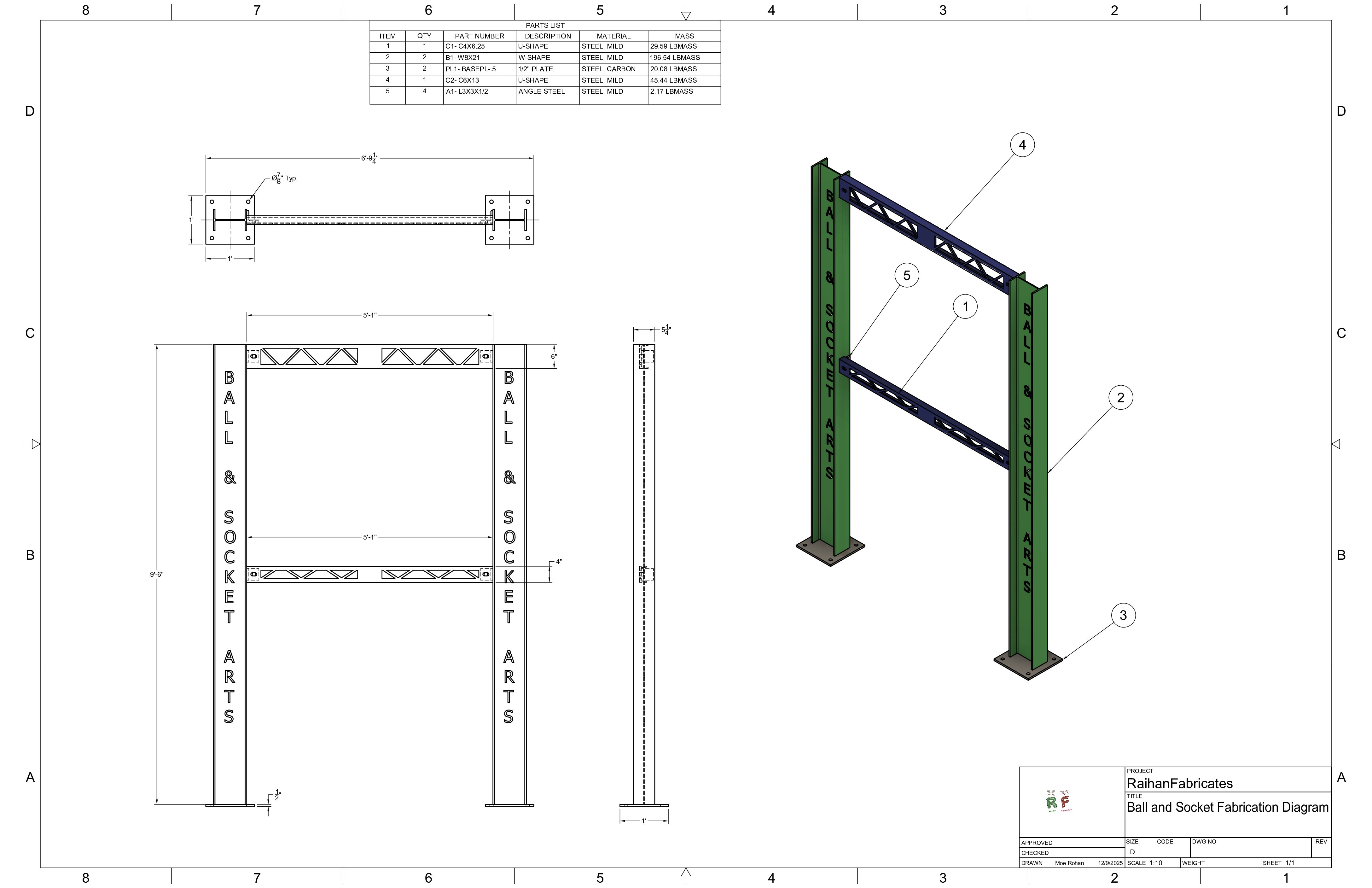

[[Voortman Drawing]]

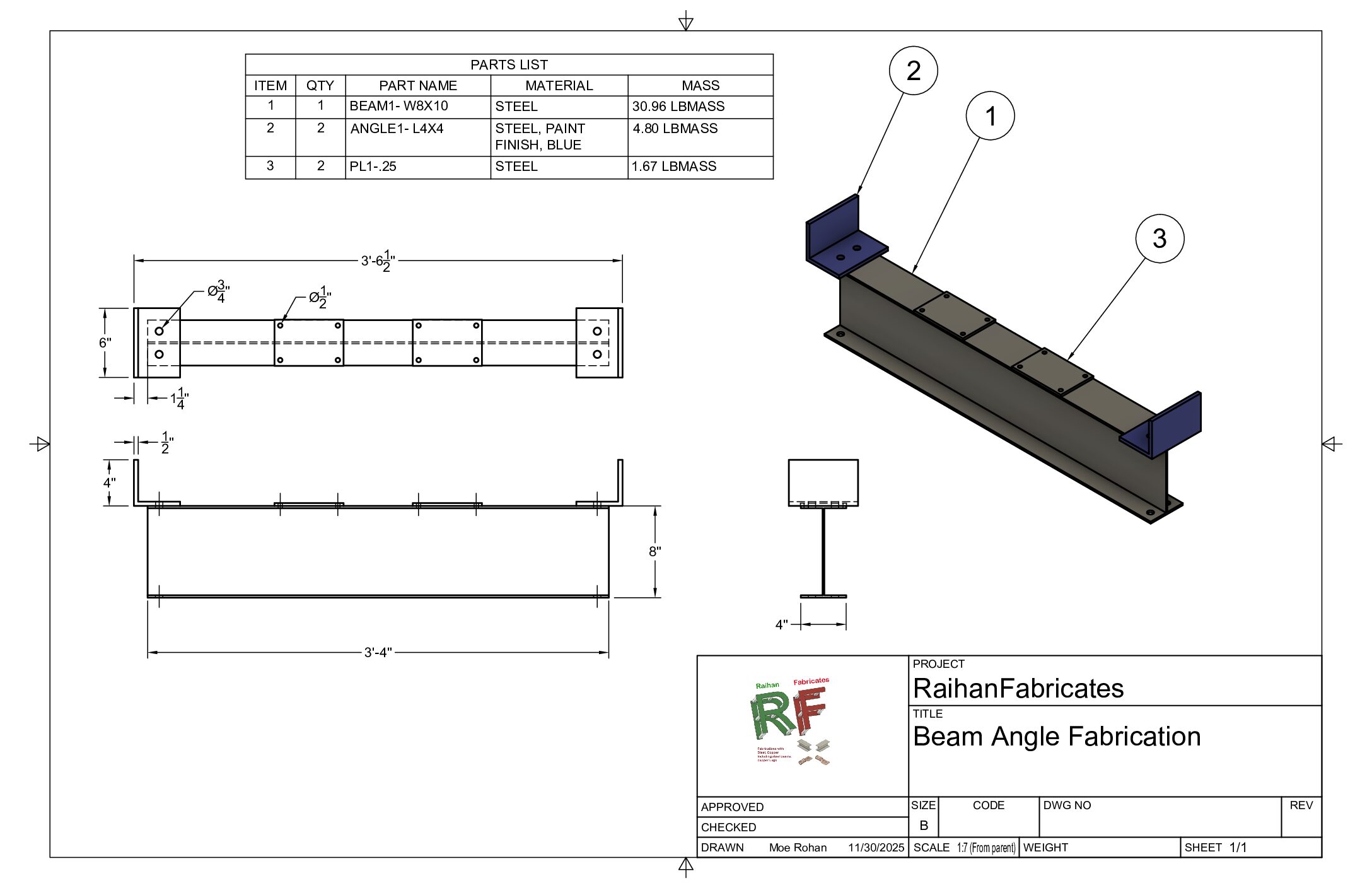

[[Angle Drawing]]

[[Channel Drawing]]

[[Beam Drawing]]

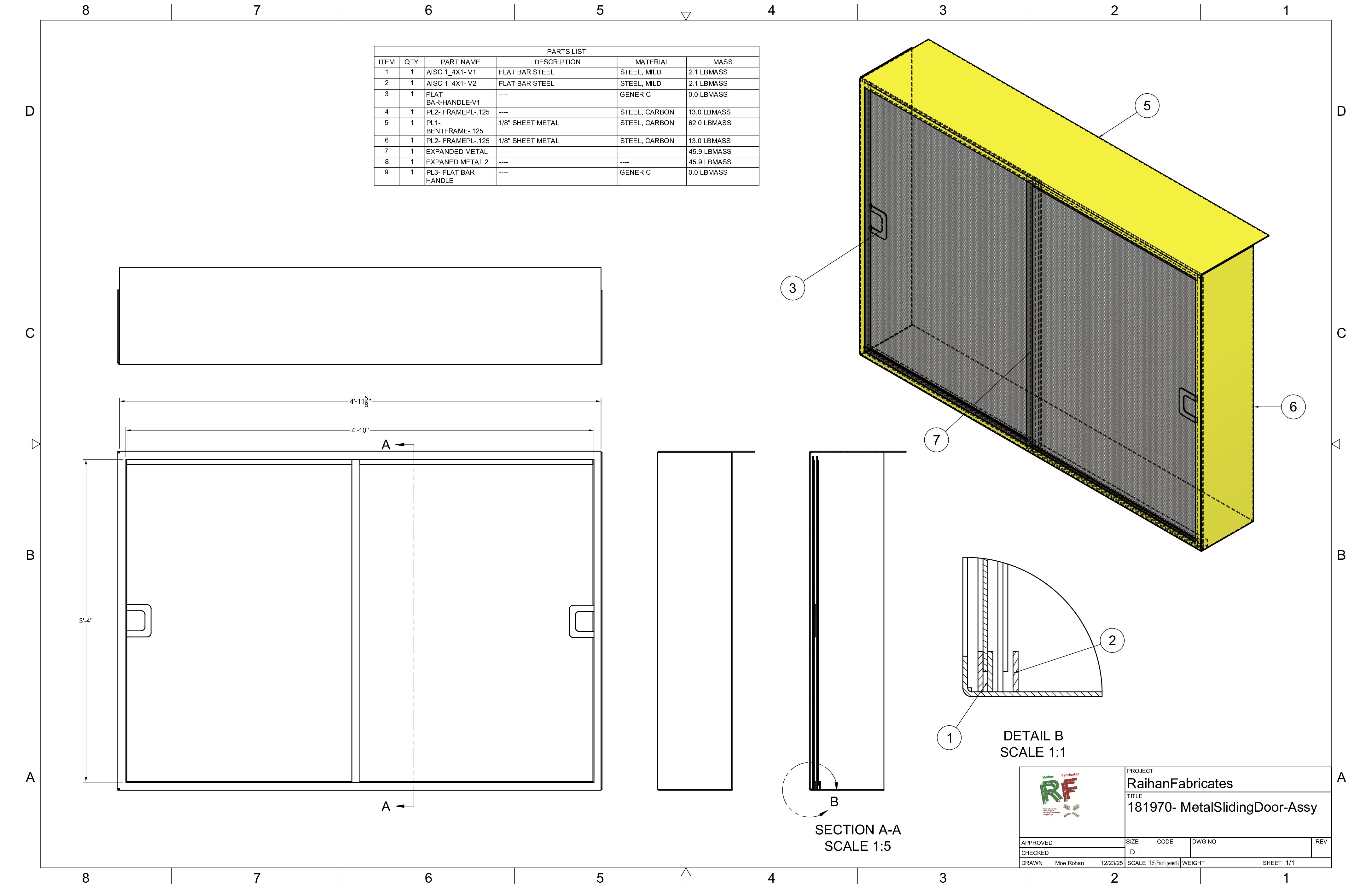

[[Fabrication Drawing]]

Hello Everyone, at RaihanFabricates. I would like to introduce another project today, that I helped fabricate at Logan Steel. This was for a company that wanted a Ball & Socket Logo designed on a few beams. And our task was to cut this on our new machine, Voortman, where the beams would have specific lettering imprinted onto the said beam. I have attached a drawing, and I will attach a video as well. In summary, it’s just a drawing, with fabricated letterings, base plates, and channels to connect the said beam, so this can be used as a sign, for the Ball and Socket Company.

I want to showcase what is possible, when appropriate knowledge is integrated. The cool thing about working with steel is, it’s not an easy thing to do. And because I worked at Logan Steel, even though my drawings may look easy, actually replicating in real life, it’s a big hassle. Each of these beam weighs hundreds of pounds, and it can only be lifted by a forklift. And it has to be brought to site, and this is only possible because proper machines are able to drill and make the proper lettering. Cause, this is not easy, and if it was, I would not be showcasing on my website, with this much excitement.

Though there are a lot of potentials for this application. And one of the reasons why I have started RaihanFabricates, it’s so that I can convey, the many potentialities that are possible. Though the right mindset is super important. And for me, showcasing the possibilities, it’s the first step to introducing what fabrication is capable of doing. And in this fabricated Ball and Socket beam sign, I want to highlight, the complexity that it entails, when we are working with super tough materials.

Cutting this with only manual machines would be a lot of work. But with appropriate machines, that Logan Steel has invested on, this project literally can be done in a week. The hardest part is acquiring proper materials, cutting the proper shapes, once it is visualized in a 3D program, and then having a designated time to weld the project. So it’s a lot of coordination, but it’s a cool thing to see, once it is finished. This is one of the reasons why I genuinely am super excited, and I want to showcase even more projects as I invest more time in this.

I have made my share of projects, and although I don’t weld myself, nor am I doing much of the physical labor involved in the process, I do intend to explain the process, as thoroughly as possible. So the people that are doing the genuine hard work, can actually sell the product, as there is so much potential.

The Ball and Socket is one of the first projects, where I just want to showcase simple design, in complex materials. Cause this is not an easy thing to do, but with appropriate machinery, and appropriate hard work, it’s totally feasible in a very short amount of time. And this is genuinely such a cool phenomenon. And as a result, I would like to showcase more projects, in the upcoming weeks, to months, to years. Though I will need help from potential clients who are willing to take the risk, to experiment with tough materials, such as steel. Thank you for taking your time reading this.

Example Ball and Socket Diagram Model: https://raihanfabricates.com/inventor/