描く Blog #1 #ZoneOneFall

Aim: 11 minutes

11/27/25: Thursday

5:14PM-5:25PM: #11mins

#600words

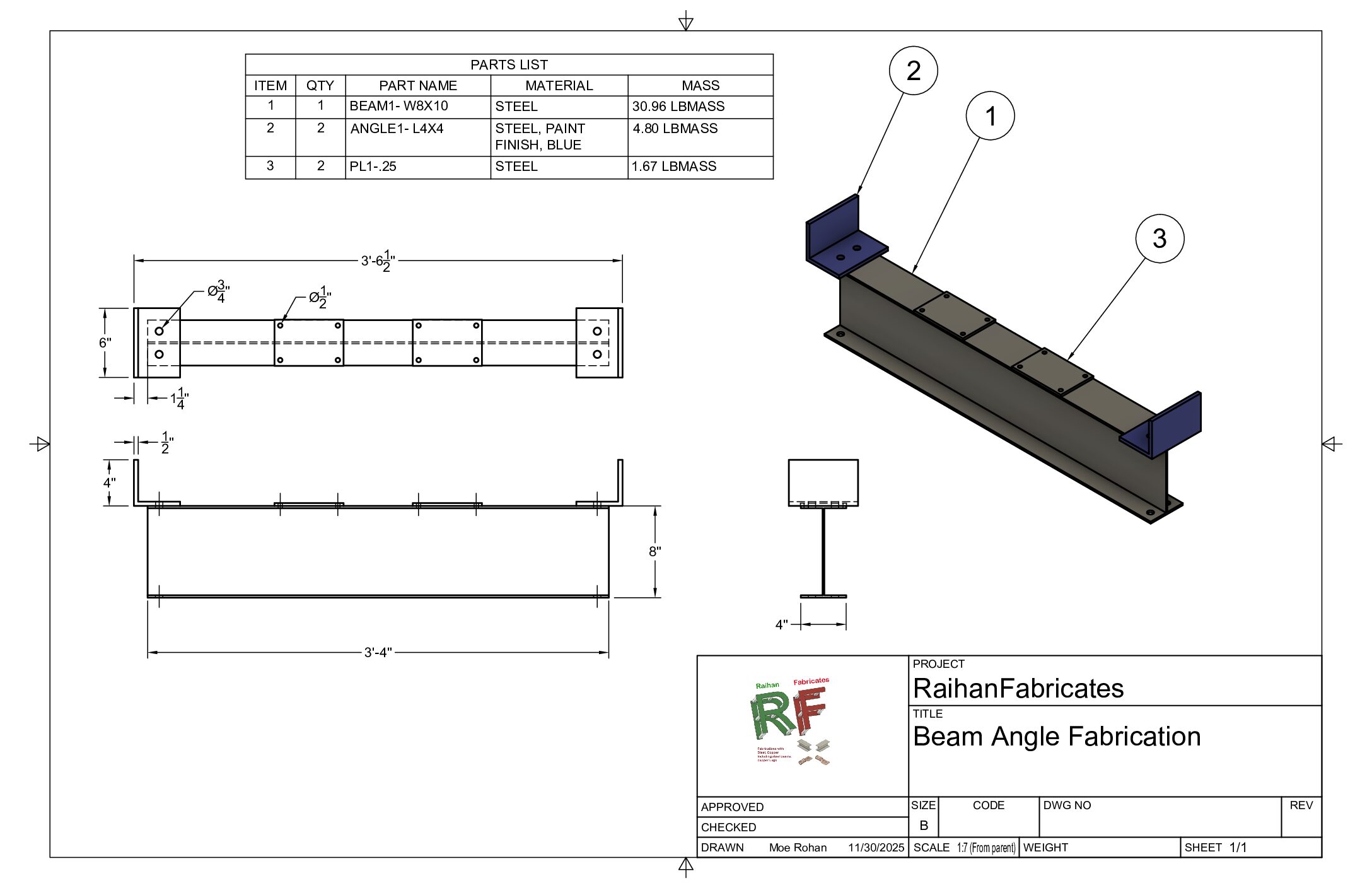

[[Angle Drawing]]

[[Beam Drawing]]

[[Plate Drawing]]

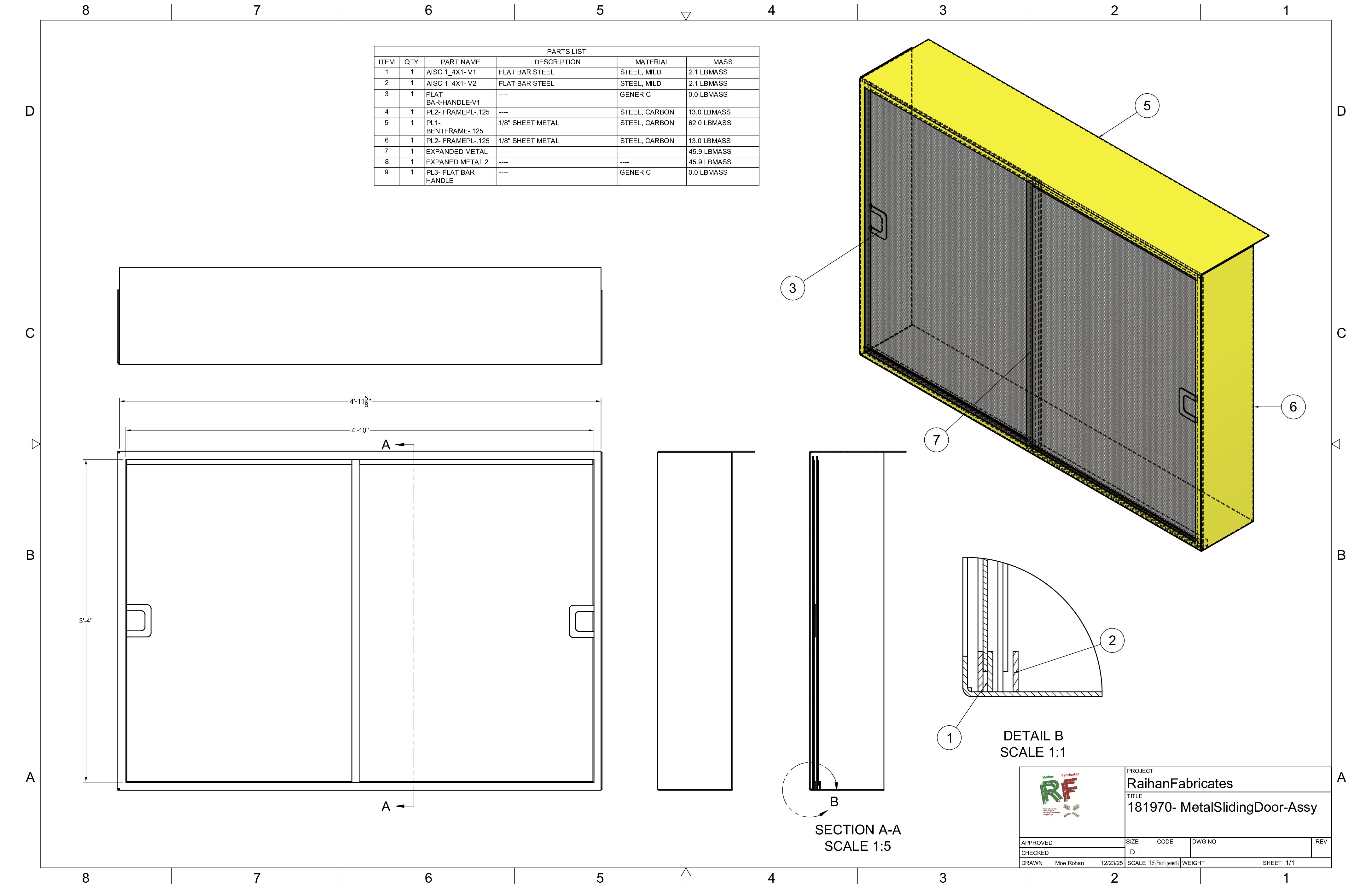

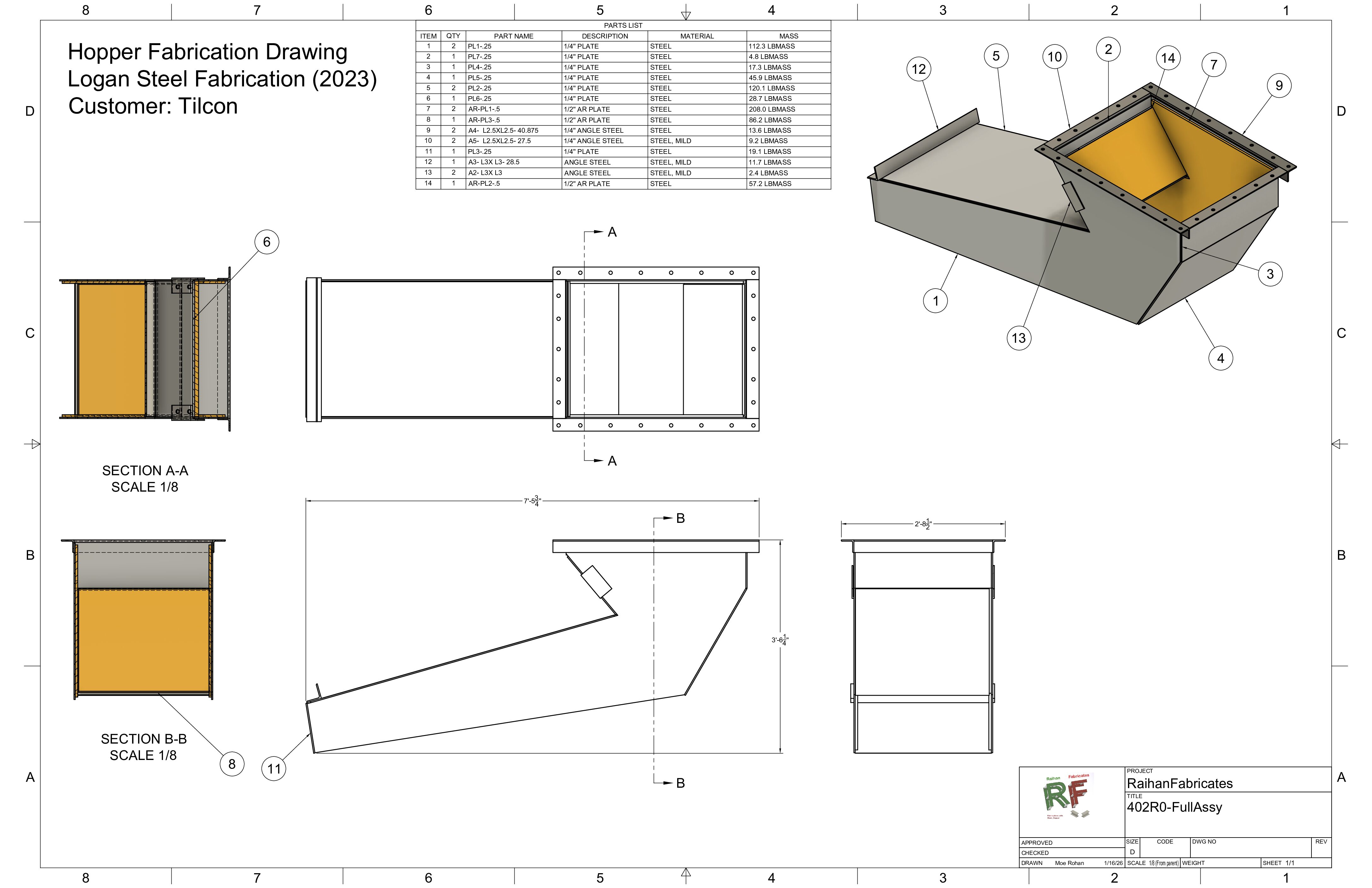

[[Fabrication Drawing]]

Today I will be writing my first blog for RaihanFabricates.com. I am going to be using a similar sprinting blogging method that I’ve been using for MrMoeRohan.com, for the past 8 months. For me, using a sprinting blogging method, has become genuinely such a cool tool. To get my thoughts out, as I slowly proceed to do what I love. I genuinely love the process of creating. And the best way to create, it’s not when the ideas spark, and it’s when you consciously decide, it’s time to create something, and you give yourself a certain amount of time.

And for me, this is a methodology to just show my work, but at the same time discuss something that not everyone is familiar with. And for today’s drawing blog, I want to talk about just a simple beam angle connection. This is a connection that will allow for piping to fit, with the support of the steel beam. It’s a structural connection, that I draw up, so it can be fabricated. I learned this while working at Logan Steel, and it’s just a simple fabrication drawing. But it has a few steps, and we have to properly drill the holes beforehand, before we can actually have it be usable on site.

And this connection requires bolts, nuts, and washers as well. This is a typical beam, angle, plate fabrication, that requires appropriate connection. Here, a beam, W8x10, and an angle, L4x4x3/8, are going to be connected to each other, when the fabricated procedures are in place. The W8 refers to the depth of the beam. And the 10 represents the weight of the beam, per 1’ length. Thus it’s referenced W8x10, and this is how most beams are named. Similarly, the angle is also similar, in the naming category. L4x4x3/8, simply means, an angle that is 4” by 4”, the thickness being 3/8”. And this is just a typical reading of how a beam and an angle work.

The drawing that I have just represents a simple fabrication for structural support. Because a pipe requires strong support, and pipe that will be going on this beam, it will also be going to a specific location, where it will have to be mounted. So it requires proper holes, before it can be taken to the site. At Logan Steel, I learned how steel fabrication works. And because steel is such a tough material, having everything done beforehand, before it arrives on site, it really genuinely does save a lot of time. Because, at a fabrication site, they have a lot more tools, that makes the whole process so much easier, compared to if you were going to do this in the field.

And I want to slowly showcase what I have learned with my drawings, over the years. And this website, it’s just a simple show my work website, at this initial phase, till I feel confident that what I’m showcasing is important to my audience. I’m intending to remotely work a lot more in the future, but before that, I want to build an audience, so I can have confidence that I will succeed appropriately in the future. So this is a demonstration of what I make, and a brief explanation, in my own words. It may be a little wordy, but this is the best way I can get my thoughts out, and actually have my audience understand what I’m talking about.

Nice.